Challenges

There is a continuing demand for temperature sensors that accurately and quickly measure fixing temperatures in the fixing units of printers, copiers and printing machines. These temperature sensors were initially made of glass. But strong contact pressure on the fixing roller easily damages glass thermistors, causing image quality to deteriorate, and they consume large amounts of power. So improvement was necessary.

Efforts to address challenges

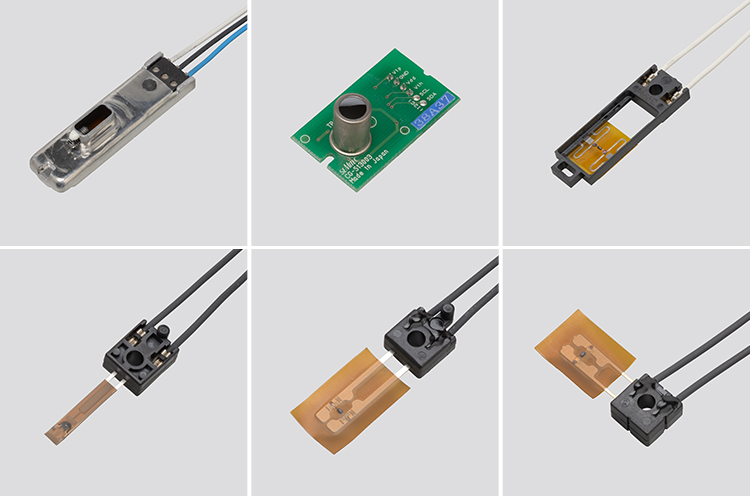

We developed and continued to improve a new contact-type fixing temperature sensor equipped with SEMITEC’s unique thin-film thermistor. In recent years, we put three contact-type products on the market that enhance image quality and save energy. Currently, it has become a well-established sensor adopted by most OA equipment manufacturers in the Japanese, European, North American, and Asian markets. The contact-type temperature sensor is mounted on a rotating fixing roller and the product suppresses roller scratches that affect the quality of printed matter. The basic structure combines a thin-film thermistor with a springy frame. The FS sensor (low contact pressure) is a mainstay product with a flat structure and minimal contact area that reduces contact pressure and prevents damage to rollers, thus solving the main problem. In addition, we offer a lineup of HF-H (High-speed) sensors with a structure that improves response and reduces heat loss, as well as HF-L (Low-cost) sensors with a simple structure that minimizes price.