Introduction

Conventional NTC thermistors are based on chips with electrodes formed on ceramics made by sintering composite metal oxides composed of manganese, cobalt, nickel, iron, and other metals.

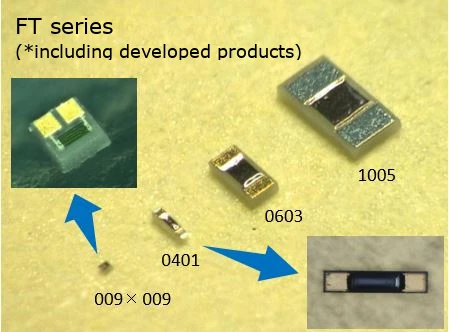

Thin-film thermistors (FT series) are proprietary thermistors that we commercialized before anyone else by combining the production and management methods of conventional thermistors cultivated at SEMITEC with semiconductor process technologies based on Si wafers, such as surge absorbers (VRD) and current regulative diodes (CRD).

Thin-Film Thermistor “FT Series”

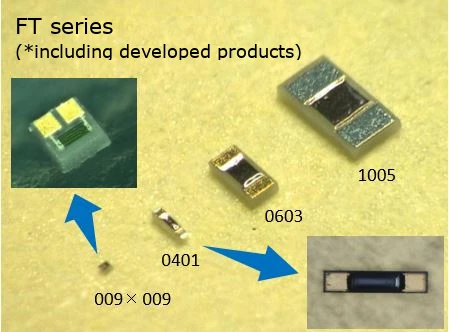

The FT series consists of an NTC thermistor formed on one side of a thin alumina substrate (standard 0.15 mm thickness). The thickness of the constituent electrodes and thermistors is on the submicron order, and they are uniform and highly productive thermistors miniaturized by semiconductor technologies such as photolithography.

Thin-film thermistors are thinner and smaller in volume than other thermistors, resulting in a smaller thermal capacity of the thermistor, enabling high-speed temperature measurement in confined spaces where installation and measurement were previously impossible.

The FT series has electrode types suitable for the connection method (soldering, wire bonding, conductive adhesive).

Currently type 1005 (1.0×0.5mm) and type 0603 (0.6×0.3mm) have been released.

Working example

Here is an example of an implementation that takes advantage of the features of the FT series.

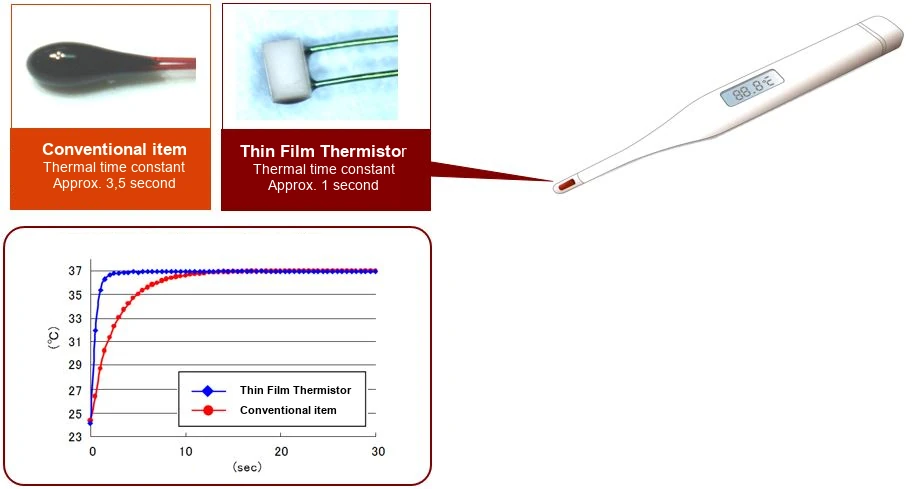

Electronic thermometer

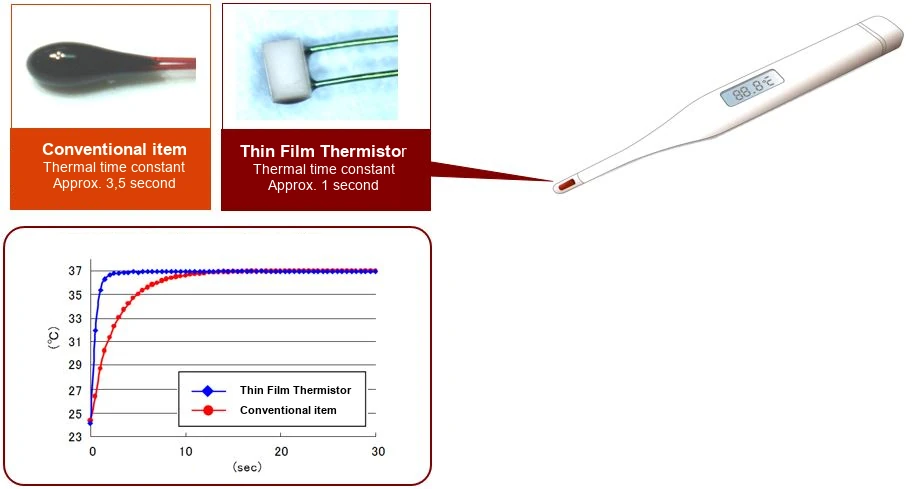

The FT-ZM, which uses a thin-film thermistor, was developed for use in electronic thermometers for high-speed measurement.

Conventional thermistors used for electronic thermometers are leaded, and the heat-sensitive part is coated with glass or resin for insulation and has an oval shape.

The FT-ZM, on the other hand, consists of a small thin-film thermistor FT with a lead wire on one side.

Since the insulating part (alumina) of the FT-ZM is flat, surface contact of the FT’s insulating part with the thermometer probe improves thermal coupling between the thermistor and the probe, enabling high-speed temperature measurement.

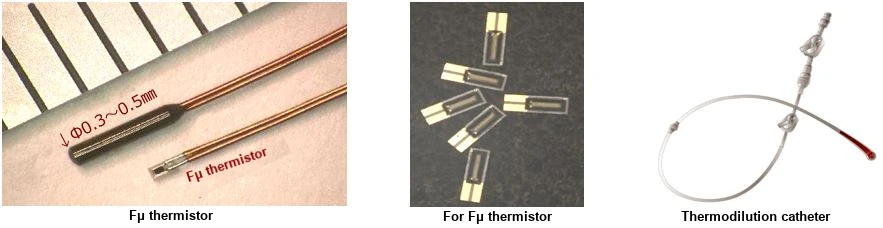

Temperature sensor for catheters

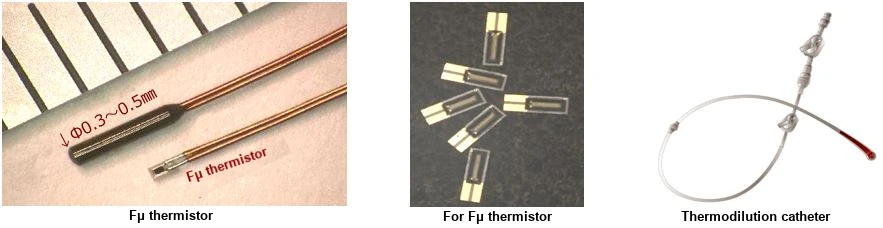

The Fμ thermistor, which uses a thin-film thermistor, is used in thermodilution catheters.

A thermodilution catheter is an examination catheter inserted into the pulmonary artery of the heart to measure cardiac output.

The principle behind the measurement is to supply a fixed amount of low temperature saline solution to the heart via a catheter, and downstream, the temperature of the blood is monitored by a temperature sensor placed inside the catheter, and cardiac output is calculated from the time taken for the temperature to start changing and return to normal, requiring high responsiveness and high temperature precision in the temperature sensor.

The Fμ thermistor is a small thin-film thermistor with electrodes arranged in a different way, resulting in a thermistor sensor with an ultrafine lead wire suitable for catheters that can be inserted into small diameter holes.

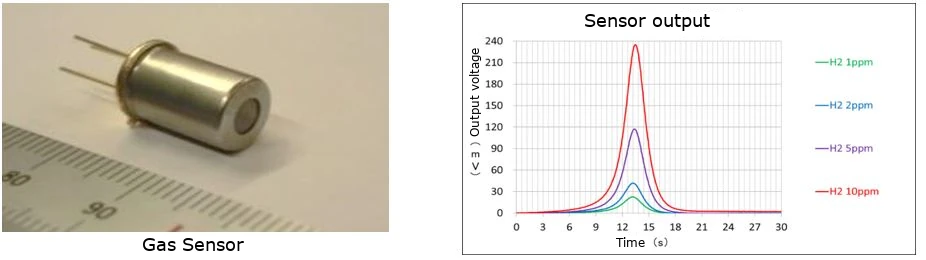

Gas sensor

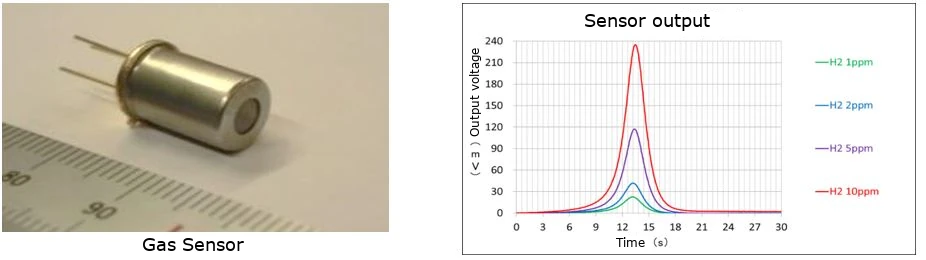

SEMITEC’s unique gas sensor with high gas selectivity has been developed by combining a thin-film thermistor and a porous gas molecule adsorption material (patented)

The gas is sensitive only to hydrogen, helium, ammonia, and water vapor.

As for hydrogen gas, we have successfully detected a gas concentration of 1ppm, which could be used for medical applications such as exhaled breath and skin gas.

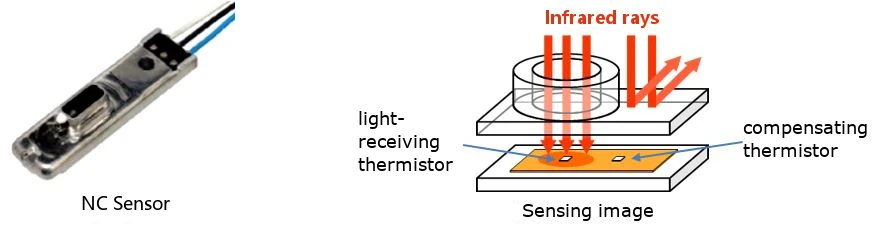

Non-Contact Temperature Sensor: NC Sensor

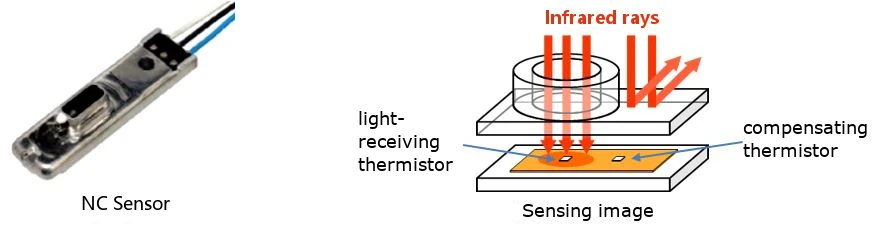

Using two thin-film thermistors, SEMITEC has developed its own non-contact temperature sensor, the NC Sensor.

To use a thermistor to measure the temperature of an object without contact, it is necessary to reduce the heat capacity of the thermistor on the side that receives infrared rays from the measured object so that it can track minute infrared ray changes.

In the case of non-contact temperature measurement, temperature is converted from the difference between a thermistor that receives infrared rays from the measured object (light-receiving thermistor) and a thermistor that does not receive infrared rays (compensating thermistor), so the two thermistors must have similar characteristics when placed in the same environment.

Thin-film thermistors are produced using a semiconductor process, making it easy to pair thermistors with similar characteristics within a wafer, and their small heat capacity makes them suitable as non-contact temperature sensors.

Used in temperature control applications for heat fusing rollers in printers and copy machines.

Contact Temperature Sensor: Fusing Sensor

Taking advantage of the features of thin-film thermistors, contact temperature sensors and fusing sensors have been developed for temperature control of heat fusing rollers in printers and copy machines.

FS and HF sensors are available as a series of fusing sensors.

The heat fusing roller must be temperature-controlled at high temperatures, such as 150℃ to 200℃, and the temperature rise is very fast, so the temperature must be taken quickly.

There was also the problem that the rollers were rotating and the sensors that made contact with them could scratch them, resulting in reduced print quality.

SEMITEC’s fusing sensor uses a thin-film thermistor that is extremely compact, can withstand high temperatures, and has a flat contact surface. Having improved on those metrics, the sensor has been adopted in many cases.

Power semiconductor

Power semiconductors are responsible for supplying electric power to various electric devices and nowadays, electric vehicles (xEV).

SEMITEC’s thin-film thermistors have attracted attention for temperature sensing of these power semiconductors.

For example, in an EV vehicle, a DC battery is converted to AC by an inverter equipped with a power semiconductor to propel the drive motor (AC).

Silicon (Si) has been the main material used in power semiconductors, but power semiconductors, which use large amounts of power even compared to other semiconductor components, have the problem that in addition to power consumption for operation, some power escapes as heat (power loss) when current is applied. Therefore, power semiconductors using SiC (silicon carbide) and GaN (gallium nitride) have been developed as new semiconductor materials that conduct electricity more readily and incur less power loss than silicon, and are now being brought to market (SiC-MOSFETs, etc.).

These power semiconductors have enabled EVs to achieve even higher efficiency, and have also contributed to making them more compact and lighter, thereby extending their cruising range.

While conventional power semiconductors using silicon (Si) have a heat resistance temperature of 150℃, power semiconductors using SiC and GaN have a heat resistance temperature of 250℃, allowing them to operate at higher temperatures.

Temperature sensing is essential for efficient operation of power semiconductors. Ordinary surface-mount thermistors (chip thermistors: heat resistance temperature of 150℃) have been used in many cases, but the operating temperature of power semiconductors using SiC and GaN is high (250℃), so ordinary surface-mount thermistors (chip thermistors) could not be used.

This is why SEMITEC’s thin-film thermistors, which are characterized by their thin profile, compact size, and high heat resistance (up to 250℃), have begun to attract attention as a next-generation power semiconductor application.

Thin-film thermistors for power semiconductors (example)

Future developments

SEMITEC will continue to further miniaturize and improve the precision of its thin-film thermistors to achieve high-speed, high-precision temperature measurement of very small spaces and very small measured objects, which was not possible before.

Furthermore, SEMITEC will continue trying to develop new proprietary SEMITEC sensors by taking advantage of the features of thin-film thermistors and combining them with various technologies and new materials.