With the global epidemic of infectious diseases, temperature measurement became routine. In particular, with the spread of forehead thermometers, non-contact thermometry has become very familiar then various questions are come up. What is the principle of non-contact? Can it be measured accurately? This article introduces the types and principles of infrared sensors and non-contact temperature sensing, including thermopile sensors which are used in forehead thermometers.

About IR(infrared rays) temperature sensor

IR temperature sensor uses thermal energy transfer to measure temperature.

There are three types of thermal energy transfer.

(1) “Conduction” transmitted directly by contact (2) “Convection” through gas or liquid (3) “Radiation” by IR.

-

-

Conduction

-

-

Convection

-

-

Radiation

Non-contact temperature measurement applies the principle of radiation by IR which is described ③.

Type of IR(infrared rays) temperature sensor

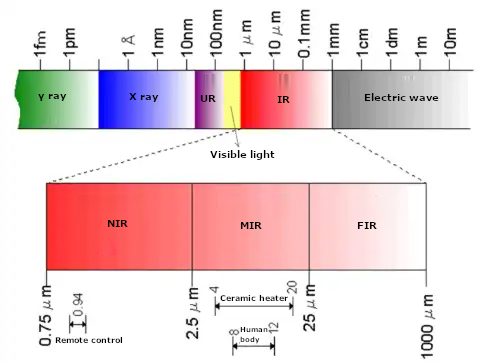

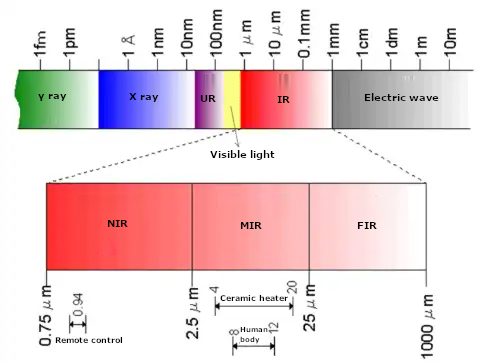

IR sensors are different from other IR sensors for communication, such as remote controls, and the sensor detects light that is closer to heat than light.

There are various types, but in principle there are two types, one is called quantum type and the other one is called thermal type.

The quantum type perceives infrared rays as light, and the thermal type perceives infrared rays as heat.

Main types and features of IR temperature sensors

①Quantum type :High sensitivity, small, high cost

②Thermal type :Low sensitivity, low cost

1. Thermistor (bolometer) type :Temperature change is detected by the resistance value change of the resistor.

2. Thermopile type :Temperature change is detected by thermal electromotive force of thermocouple.

3. Pyroelectric type :Temperature change is detected by the electric charge which is generated by the pyroelectric effect.

SEMITEC’s IR temperature sensor is thermal-type IR sensor and it is available in thermistor and thermopile types. The features of each are as follows.

・Thermistor type :Large output signal, high heat resistance temperature but low responsitivity.

・Thermopile type:Compact size and high responsivity, but small output signal

Features of thermal IR temperature sensor

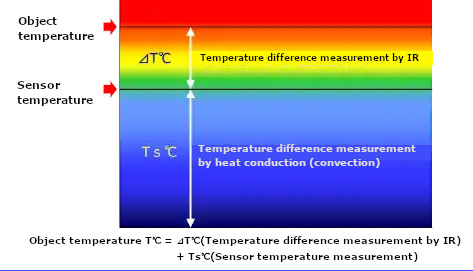

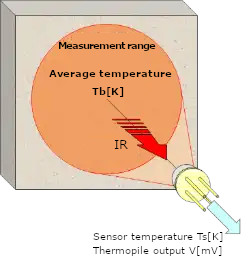

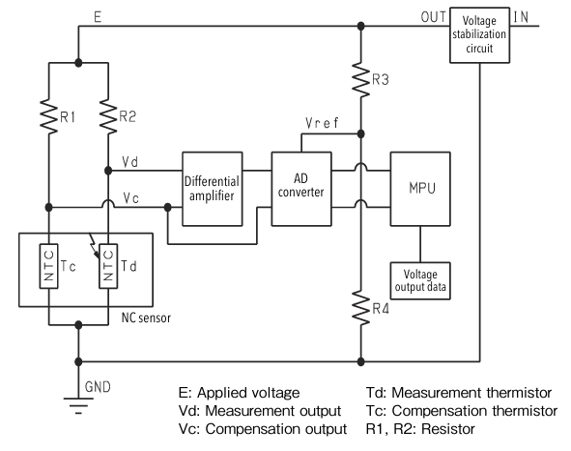

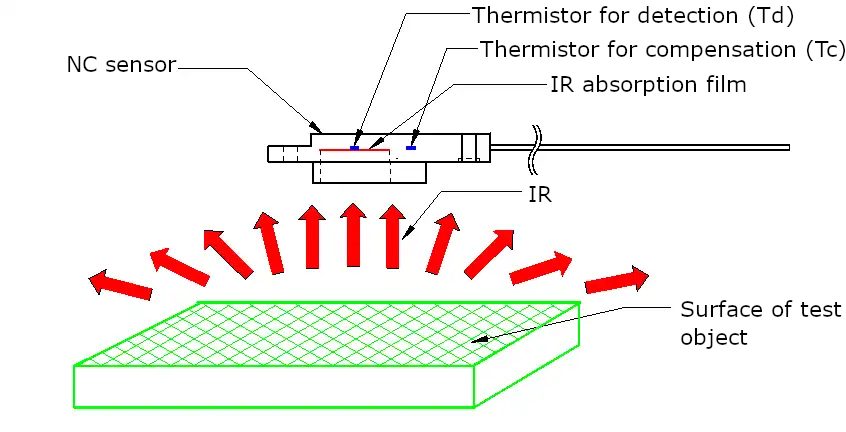

IR sensors can be used as non-contact temperature sensor but more specifically, it is the non-contact temperature difference sensor. Therefore, in order to use it as a temperature sensor, two types of information are required: temperature difference and sensor temperature. IR sensor cannot measure own temperature so it has to measure own temperature with other temperature sensor (such as a thermistor).

In other words, accurate non-contact temperature sensing requires not only IR sensor but also temperature sensor which measures the sensor itself. In the case of non-contact temperature sensing, the Stefan-Boltzmann’s law applies to the exchange of IR energy between the object to be measured and the sensor.

What is important here is that the characteristic of infrared radiation (emissivity) varies depending on the object to be measured.

When we look at an object, we cannot clearly see the color of something that is transparent such as glass but we can see the color of the object that we see through. Also, something that reflects like a mirror can only see the color of what is reflected in the mirror. IR is also very difficult to measure what is transmitted or reflected in infrared rays, and in order to measure accurately, it is preferable to have a high emissivity that is not transmitted or reflected. The forehead has a relatively high emissivity and stability, so it can be said that it is suitable for non-contact temperature measurement.

Even so, the surface temperature of forehead varies greatly depending on the outside temperature, so it may be difficult to measure body temperature accurately.

SEMITEC’s IR sensor is thermal-type sensor and our lineup of non-contact temperature sensor includes thermopile sensor using thermocouple and NC sensor which our proprietary thin-film thermistors is used. Both of these sensors are equipped with high-precision thermistors that can accurately measure the sensor itself.

SEMITEC’s non-contact temperature sensor

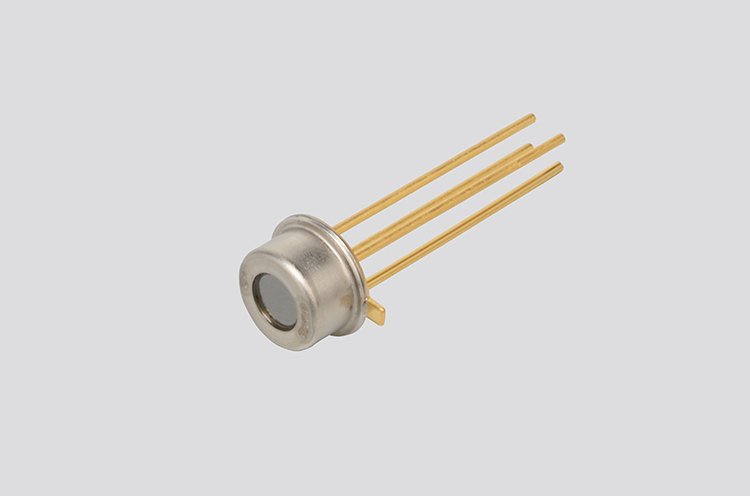

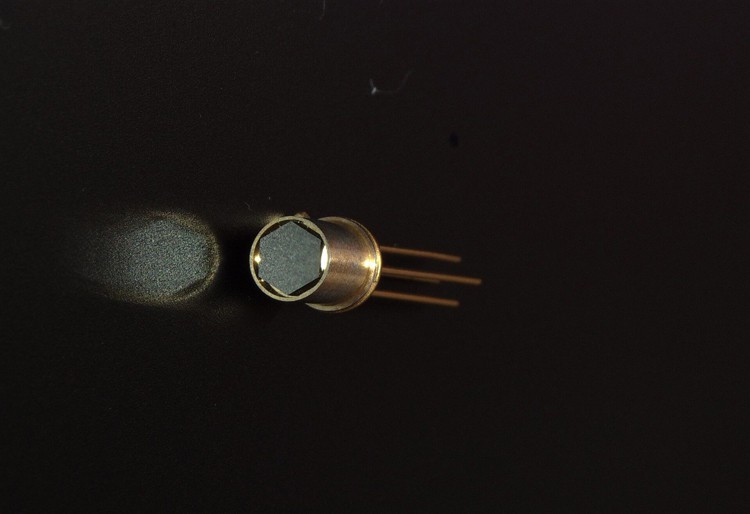

・Thermopile sensor

This IR sensor is mainly used in ear type thermometers and forehead type thermometers, and it is applied the principle of thermocouple. It is manufactured by original silicon micromachining technology using semiconductor process, and realizes high sensitivity and fast response.

V = α(Tb4‐Ts4)

V :Thermopile output [mV]

α :Coefficient

Tb:Absolute temperature of the object [K]

Ts:Sensor absolute temperature [K]

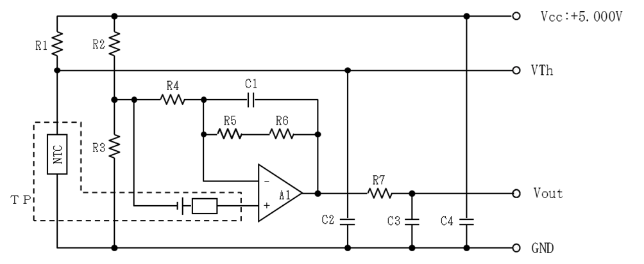

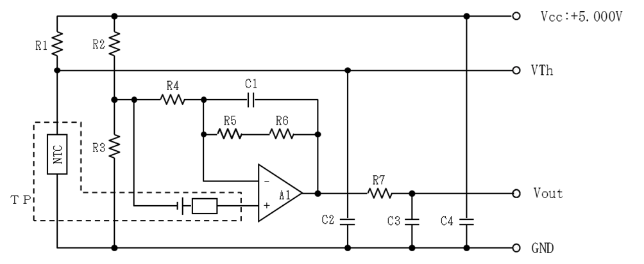

The responsivity is fast and the sensitivity is high but the output signal is small so the amplifier circuit is used. In addition, since the output characteristics is unstable, the adjustment is necessary for use as a thermometer.

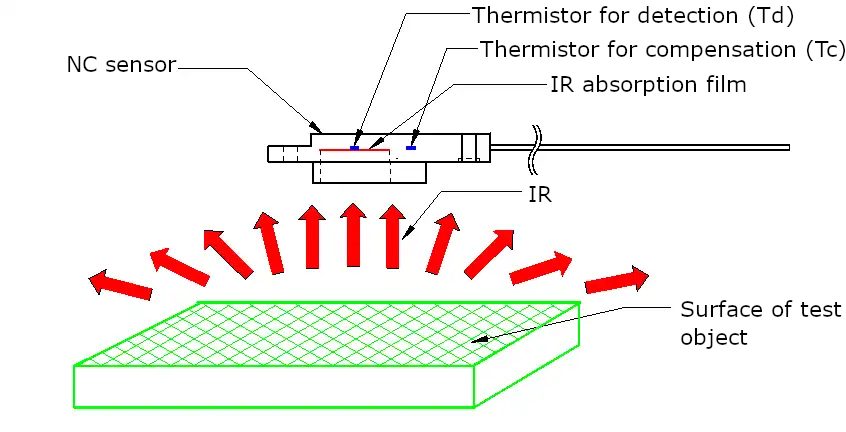

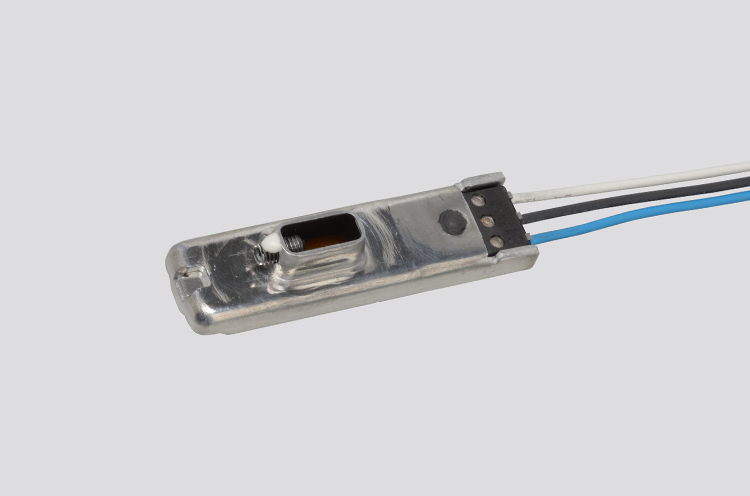

・NC sensor

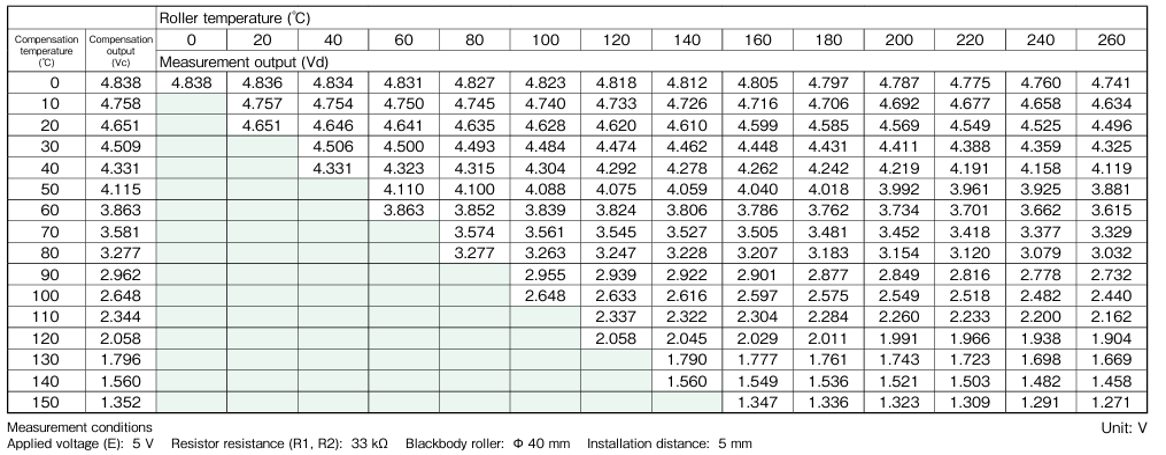

SEMITEC’s original non-contact temperature sensor is based on a thin-film thermistor* which is mainly used in office automation equipment such as copiers and the world’s first successful mass production. It is resistant to dirt and can be used in an environment of 150°C, and has the advantage that an amplifier circuit is not required depending on the conditions.

※According to our company survey

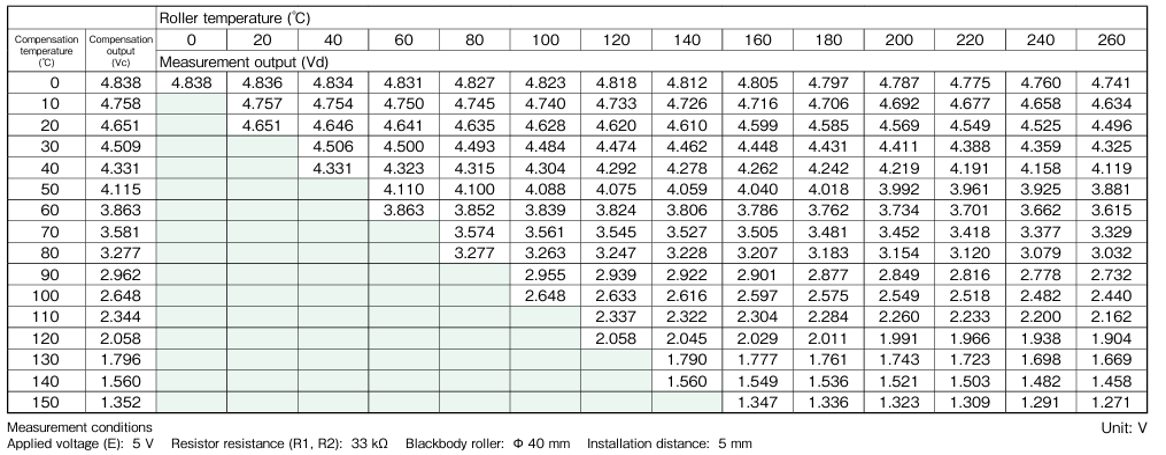

Both thermopile and NC sensors are approximated by the Stefan-Boltzmann’s law which was described above. However, depending on the operating conditions, the output may change due to signals other than IR energy (secondary radiation, noise and etc. due to temperature drift) so it is necessary to correct for each operating environment. In particular, since NC sensors are used close to the object to be measured, the influence of temperature distribution and convection in the measurement area is large. For non-contact temperature measurement, accurate measurement is possible by using table data with temperature correction.

In this way, non-contact temperature sensors are very convenient, and accurate temperature measurement is possible when used with due consideration to the principle of infrared measurement, sensor performance, and operating environment.